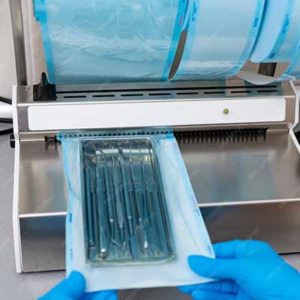

Sterilization packaging solution

Sterilization Gusseted Pouch

Key Features:

- Precision manufacturing in stringent sizes

- Available indicators: EO (Ethylene Oxide) and STEAM

- Compliance with EN 868-5 standards

- Constructed with multilayer polymer and medical-grade paper

Tyvek Sterilization Bags: Engineered within an ISO Class 5 Clean Room, Tyvek sterilization bags are designed to meet the highest standards in the sterilization of critical components. They exhibit exceptional performance in terms of cleanliness, material strength, sealing integrity, and microbial barrier properties. These autoclave bags, made from breathable, medical-grade Tyvek, are compatible with various sterilization methods including Steam and ETO (Ethylene Oxide) sterilization. The bags feature a multilayered extruded medical-grade HDPE.

Material:

- DuPont Tyvek

- Medical-grade HDPE

Features:

- Complete Tyvek sterilization packaging within a certified ISO Class 5 Clean Room dedicated to the production of these bags

- HDPE film made from certified virgin resins in an ultra-clean environment without additives

- Ultra-clean autoclave bags with minimal particle generation

- Superior resistance to microbial penetration, preventing microbial growth

- High sterility integrity maintained until the package is opened

- Low particle generation upon opening the bag

- Strong and durable with high resistance to tearing and puncturing

- Sterilization indicator that changes color when exposed to steam

Applications:

- Stoppers, caps, and closures

- Vials and containers

- Syringe components

- Stainless steel laboratory or process equipment

- Medical devices

- Cleanroom garments, silicone tubing, and all stainless steel and glass materials used in pharmaceutical and hospital settings

Sizes:

- Customizable sizes ranging from 100 mm x 100 mm to 1000 mm x 1000 mm tailored to customer requirements